We compare 7 carvers side-by-side

Table of Contents

From left to right: SCM Original Power Carver (entry level), SCM Power Carver (entry level), Shofu Lab Air-Z (rebranded SCM Power Carver 400xs), Powercrafter, NSK Presto, Unbridled Vortex XJ7, Turbo Carver.

Lets start our comparison by watching two unbiased videos by Roger Wolford

Engraving Glass, by Roger Wolford

What is common with all the carver? The cutting bur.

When it comes to selecting a high speed carver, how do you decide which one to purchase? You start with the business end, the cutting bur. This is the first criteria you need to examine. The bur is the part that does the cutting and they all have one thing in common, the shaft diameter is 1/16 of an inch or 1.6mm. This size bur is commonly know as a Friction Grip bur of FG for short. All the carver use the FG size bur. The actual cutting head is attached to the shaft and comes in many different shapes and sized. Only high quality burs should be used for carving. Most burs are rated for 360,000 – 500,000 RPM. The speed of the tool must be run lower than the bur’s maximum RPM rating or you risk injury. If you run the tool faster than the bur’s rated speed, the bur could disintegrate causing injury.

Power or RPM?

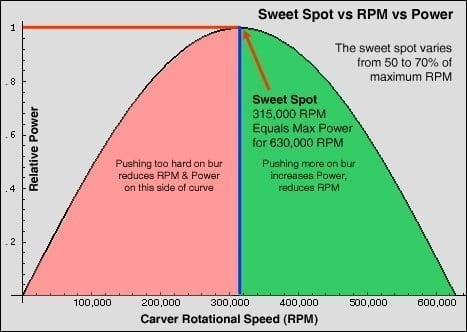

The answer is both. Like an automobile engine measured in horsepower and torque, we measure carvers in Watts instead. This is where RPM (how fast the bur is spinning) comes into play. If you have low RPM and high torque, you will have low power carver. Likewise, high RPM and low torque will get you a low power carver. What is best is high torque and high RPM to give you a high powered carver.

Carvers range from just a couple of watts of power up to 20 watts. A good rule of thumb is to look at the maximum RPM and the amount of air consumed. Higher RPM and more air consumed usually means higher power (Watts).

What is the "Sweet Spot "?

Air Pressure & Turbine Bearings

Is there an ideal air pressure to run a carver? Carvers running at lower air pressure lack enough power to cut. At higher pressures, the RPM will be great, but the life of the turbine is compromised and short lived. Permanently lubricated bearings are designed last 1,000 to 2,000 hours with a maximum air pressure of 38 PSI. Higher pressures of 45 PSI or more are reserved for wet bearings, meaning they require a drop of oil every 20 minutes to an hour of use. Ideally, a carver requiring an air pressure of 30-38 PSI is a good range for carving.

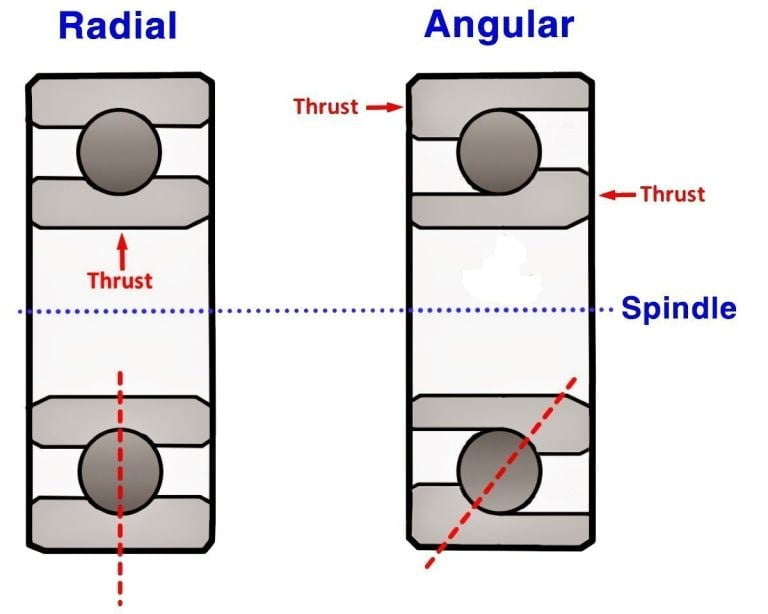

An interesting side effect when carving is the ability of the bearings to handle lateral loading. This is the ability for the bearings to handle the sideways cutting when carving. Since carving is not the same as drilling, most of the force the bearings see is sideways and not downwards. Small diameter bearings have a high failure rate, while large diameter bearings are able to take the load much better. Carvers are designed using two bearings holding something called a “spindle”.

The spindle holds the bur in place as you carve. If the bearings on the spindle are close to each other, they cannot handle the lateral force, the sideways carving. Bearings spaced further apart on the spindle, not spindle length, are much better for obtaining a longer bearing life. Ideally, radial bearings giving more stability with lateral pressure from carving on the side of the bur. Carvers with a plunger usually use angular bearings because the burs are inserted into the spindle by pressing down vertically on a hard surface.

Time to check out the carvers

Test Equipment

Full disclosure, Unbridled have sold Turbo Carvers, Powercrafters and Power Carvers for many years, but elected to discontinue their product lines. We discontinued selling the Turbo Carver brand due to poor reliability. The Powercrafter brand went out of business. We discontinued the SCM Power Carver line due to turbine failures and lack of quality.

Specifications

- Accumulator Air Tank, 3 Gallon

- Pressure Regulator, SMC ITV2030, 0.005-0.5 MPa (0-72.5 PSI), 0-5 Volts

- Volumetric Flow Rate, Mass Flow Meter, Sierra Instruments, 0-5 Volts, 0-70 SLM

- Pressure Gauge measured at carver, SSI Technologies, 0-100PSI, 1.0% Full Scale

- Tachometer, Micron, HPW-2, 5,000-999,000 RPM, 1-200KHz

- Torque and Power, Stall Torque Method, Diameter 1.62 mm, Pressure 0.25 MPa (36 PSI)

- Noise/Loudness, Digital Sound Level Meter, 30-130dBA, 32-8.5KHz, 18 inches

Weights and Measures

The Weigh-in

We set the scale to weigh in grams. Since we are used to ounces in the United States, there is math involved. So we we did the math for you in the “Test Results” section below. If you are nerdy, take grams divided by 28.35.

Loudness Measurements

For this test, we use dB(A) Digital Sound Level Meter, 30-130dBA, 32-8.5KHz at a distance of 18 inches. This is about the distance your ears will be from the carver while carving. The meter was placed next to the artist’s ear and the tool was run for a few seconds to get a stable reading. The measurement scaled was A-weighted. A-weighting is the most commonly used of a family of curves defined in the International standard IEC 61672:2003 and various national standards relating to the measurement of sound pressure level. A-weighting is applied to instrument-measured sound levels in an effort to account for the relative loudness perceived by the human ear, as the ear is less sensitive to low audio frequencies. It is employed by arithmetically adding a table of values, listed by octave or third-octave bands, to the measured sound pressure levels in dB.

The Decibel Loudness Comparison Chart provides some interesting numbers to help you understand the volume levels across various sources and the affect on hearing.

Environmental Noise

- 30dB Whisper Quiet Library at 6'

- 65dB Normal Conversation at 3'

- 80dBTelephone Dial Tone

- 85dB OSHS Max Safe Level

- 95dB Hearing Loss Begins

- 95dB Jackhammer at 50'

- 98dB Hand Drill

- 107dB Lawn Mower

- 115 dB Rock Concert

- 125db Pain Begins

- 140dB Permanent Hearing Loss

- 140db Jet Engine at 100'

Video of Testing Process

Each carver was tested for sound pressure in dB(A) (loudness) at the manufacturer’s maximum air pressure. There is a digital air pressure gauge in the upper left of the video showing the air pressure entering the tool. After the dB(A) measurement is captured, a few seconds of carving was done to see if the loudness changed.

Mass Air Flow Measurements

Each carver have their air flow measured at the manufacturer’s specified maximum air pressure. The more air flow (larger number on the mass flow meter), the higher the power the carver is capable of producing. Carvers measured: SCM Power Carver (entry level), Shofu Lab Air-Z (rebranded SCM Power Carver 400xs), Powercrafter, NSK Presto, Unbridled Vortex XJ7, Turbo Carver.

Equipment used for measurements were “Accumulator Air Tank, 3 Gallon”, “Pressure Regulator, SMC ITV2030, 0.005-0.5 MPa (0-72.5 PSI), 0-5 Volts”, “Volumetric Flow Rate, Mass Flow Meter, Sierra Instruments, 0-5 Volts, 0-70 SLM”.

Nerdy math stuff again. We measured the pressure in Megapascal and air consumption in Liters per minute; say what? We know what you are thinking; just use good old American terms like PSI and CFM. You got it. No Nerdy Math. The video shows the results in American measurements!

Test Results: Vortex F5 vs Power Carver vs Turbo Carver

- Max Pressure1

- CFM/Lpm2

- RPM

- Loudness – dB(A) 18″

- Weight

- Carver Length

- Spindle Length

- Bearing Spacing

- Bearing Diameter

- Impeller Diameter

- Turbine Replacement6

- F/F/F/Q/Score4

- Warranty5

- Street Price6

- 38psi, 2.6bar

- 1.42/40

- 400,000 @ 35psi

- 83

- 1.8oz / 52g

- 4.5″

- 14.9mm

- 10.8mm

- 6.4mm

- 8.7mm

- $50/$1353

- 5/5/5/5/20

- Lifetime

- $43995

- 37psi, 2.55bar

- 1.67/47.2

- 304,000 @ 37psi

- 81.9

- 3.3oz / 94g

- 6.0″

- 20.2mm

- 12.0mm

- 8.0mm

- 8.8mm

- $175

- 3/2/3/2/10

- Lifetime

- $499 (400xs $550)

- 45psi, 3.10bar

- 1.36/38.5

- 387.000 @ 45psi

- 96.3

- 0.6oz / 16g

- 4.0″

- 11.5mm

- 9.6mm

- 6.3mm

- 7.6mm

- Unknown

- 1/2/2/1/6

- 6 Months

- $325

Test Results: Vortex F5 vs NSK Presto vs Shofu Lab Air-Z

- Max Pressure1

- CFM/Lpm2

- RPM

- Loudness – dB(A) 18″

- Weight

- Carver Length

- Spindle Length

- Bearing Spacing

- Bearing Diameter

- Impeller Diameter

- Turbine Replacement6

- F/F/F/Q/Score4

- Warranty5

- Street Price6

- 38psi, 2.6bar

- 1.42/40

- 400,000 @ 35psi

- 83

- 1.8oz / 52g

- 4.5″

- 14.9mm

- 10.8mm

- 6.4mm

- 8.7mm

- $50/$1353

- 5/5/5/5/20

- Lifetime

- $43995

- 36psi, 2.48bar

- 1.48/42

- 324,000 @ 36psi

- 77.2

- 2.5oz / 70g

- 5.25″

- 18.7mm

- 13.8mm

- 6.4mm

- 10.8mm

- $186

- 3/4/4/5/16

- 90 Days

- $550 (GSR $850)

- 36psi, 2.48bar

- 1.17/33.1

- 329.000 @ 36psi

- 87.7

- 3oz / 83g

- 5.5″

- 18.5mm

- 12.1mm

- 6.8mm

- 8.5mm

- $245

- 4/4/3/4/15

- 90 Days

- $498-$594

Test Results: Vortex F5 vs Vortex XJ7 vs Powercrafter

- Max Pressure1

- CFM/Lpm2

- RPM

- Loudness – dB(A) 18″

- Weight

- Carver Length

- Spindle Length

- Bearing Spacing

- Bearing Diameter

- Impeller Diameter

- Turbine Replacement6

- F/F/F/Q/Score4

- Warranty5

- Street Price6

- 38psi, 2.6bar

- 1.42/40

- 400,000 @ 35psi

- 83

- 1.8oz / 52g

- 4.5″

- 14.9mm

- 10.8mm

- 6.4mm

- 8.7mm

- $50/$1353

- 5/5/5/5/20

- Lifetime

- $43995

- 38psi, 2.62bar

- 2.01/57

- 333,000 @ 38psi

- 79.6

- 1.4oz / 40

- 4.25″

- 16.5mm

- 14.0mm

- 8.0mm

- 11.2mm

- N/A

- 5/4/5/5/19

- Lifetime

- Discontinued

- 45psi, 3.10bar

- 1.17/33.1

- 284,000 @ 45psi

- 87.2

- 2.2oz / 61g

- 5.6″

- 20.2mm

- 17.2mm

- 8.0mm

- 7.5mm

- $99 – $130

- 4/2/4/4/14

- 1 Year

- $299 NOS7

Footnotes for Test Results

- Max PSI/Bar is the recommend air pressure supplied to the carver per the manufacturer’s specifications. If you watched the video for air flow measurements, the pressure displayed on the digital pressure regulator is in megapascals (MPa).

- CFM/Lpm is a measure of how much air is flowing through the turbine. If you watched the video for air flow measurements, the digital mass flow meter displays in liters per minute (Lpm).

- Turbine rebuild price / New nosecone assembly with new turbine.

- Larger number is better – F3Q is a qualitative score for Form, Fit, Function and Quality. A perfect score would be 20.

- Turbine may not be covered or limited by the warranty.

- Prices were determined by Google searching and prior pricing sheets.

- New old stock. Limited supply.

Vortex F5 Test Carving

Internals of Power Carver, Powercrafter, Turbo Carver

All trademarks and brands are the property of their respective owners.