Spindle & Turbine Cleaner - You need this!

Spindle Anatomy 101

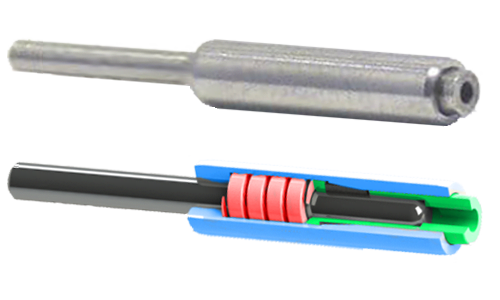

To answer this question requires an understanding what the spindle does and how it does it. Take a look at this photo. Above is the spindle with a dummy bur inserted. The button on the right side is depressed to release the bur. Looking at the X-ray view, a push button shown in green presses against the spring shown in red. When the button is pushed, the spring is compressed causing it to expand slightly, thus release its grip on the bur. This spring is the “collet.”

Get A Grip!

Dust and debris is the major cause of your bur being lose or even falling out your carver. It is the bur itself that is transporting debris into the spindle, and therein lies the problem. This debris gets caught in the coil of the spring. Once the gap between each coil become clogged, the spring can no longer grip the bur. The solution of course is to break lose the build-up on the spring and flush out the debris.

Spring Cleaning

We have developed a cleaning process that works well to break the build-up of debris on the spindle spring and flush it out at the same time. It is called “Spindle & Turbine Cleaner” for lack of a better marketing term. Our Spindle Cleaner contains 1/2 fluid ounce (15ml ) of non-toxic cleaner designed to dissolve the debris and not harm the turbine bearings or o-rings.

Back Cap - Open Detent Position

Back Cap - Close Detent Position

Step-By-Step Vortex F5 Spindle & Turbine Cleaning Guide

- Place a paper towel on you counter. This will capture the cleaner during flushing.

- Remove bur from your carver

- Turn the back cap to the “open” position. This will prevent cleaner from entering the bearings.

- Hold your carver horizontally

- Insert cleaner needle into spindle until it stops. Now move it back about 1/8 of an inch.

- Squeeze the bottle until cleaner begins to run out of the spindle

- Remove the needle from spindle

- Hold your carver vertical with the nosecone pointed down towards the paper towel

- Work the back cap by opening and closing it several times

- Repeat steps 3 – 8 two more time

- Close the back cap without a bur in the spindle and run the tools for 10 seconds to remove remaining cleaner

Tip to keep your spindle spring and turbine cleaner

Just before you insert a bur into your carver, use your thumb and index finger to wipe the bur shaft clean. This will reduce the amount of debris entering your spindle and obstructing your collet spring.